Commentary

-

Our commentary partners will help you reach your own conclusions on complex topics.

Hi, everyone, Peter Zeihan coming to you from downtown Austin, Texas. I used to live right there about three years ago. So now that I’m in Austin, I figure it’s time to talk about El Paso because I was supposed to do this in El Paso, but the Russians went and had a big strategic retreat that was the most humiliating…humiliating military retreat we’ve seen in any country since at least World War One.

Anyway, let’s talk about El Paso. The thing to remember when you’re talking about the Texas manufacturing world is there’s a lot going on.

Americans love to invest in Texas because it follows American law, the tax rates are low, land is cheap, there is no state income tax, power is cheap, food is cheap. So it’s fairly easy to convince people, especially people in their 20s and 30s…to move to the state. If you want to do tech, you usually come to Austin. If you want to do heavy manufacturing, you’re usually talking about the Houston area. If you want to do finance, Dallas is a logical option.

But one of the things that we are going to see in the world of manufacturing moving forward is that we need roughly two million manufacturing jobs in the United States just to handle electronics. And this is everything from office equipment to computer peripherals to toys. Things that normally the United States would have offshored to the east Asian countries years, if not decades ago. With the Germans and the Chinese facing increasing headwinds in their own economic and political systems, a lot of this stuff is going to have to come back. Not because of competition, although there is competition. But because the Germans and the Chinese aren’t going to be able to make the stuff and Americans will have the choice between making it locally, or not having it all.

Now the manufacturing supply chain for electronics is significantly different from what it is for other parts. So let’s say you’re making an airplane. Yes, there are different technological levels. The people who do the seats do some things, the people who do the plane or the…engines do another thing. And it’s different skill sets. But there are a few enough planes and it’s value added sufficiently that you can…it doesn’t really matter how you get those parts back and forth. And so in the case of Europe, they fly them in many cases or have custom-made barges. But if you’re going to make like, a CD player – do we even have CD players anymore? That’s probably a bad example. You’re gonna make an iPod…I’m losing track here. Let’s say you’re gonna make a modem.

You’re talking about making things en masse, and they have different components. So you know, the person who is going to put together the casing, which is probably a diecast or an injection mold, has a different skill set than the person who is doing the wiring harness, is a different person from the person who’s assembling the motherboard, is different from the person making the transistors for that motherboard, and so on. Each of these is a different skill set. There are dozens, if not hundreds of parts for any electrical piece of equipment or toy or tool. But all of those components have their own supply chains and their own worker needs. And they’re all at different price points because the skill is different.

So unlike say, assembling a semiconductor where it’s all done in a single facility in a cleanroom, when you’re making electronics, you need several, dozens, maybe even hundreds of different facilities with different workforces with different skill sets at different price points. And that’s the key thing. So it’s very rare for all of these various price points to be present within the same political entity.

So think of the United States. The richest state is Connecticut, the poorest one is Mississippi. But the income difference between the two is less than a factor of two and a half. That’s not enough to justify electronics manufacture en masse in the United States. Which is where Mexico comes in. Mexico is skilled and getting more skilled by the day, but the cost relative to American labor is much lower as is the skill set. So you can do some of the higher tech stuff north of the border, while the lower tech, more labor intensive stuff, south of the border. And this is one of the reasons why Southeast Asia excels so much as an electronics manufacturer. Because there’s different value sets. You’ve got the Chinese for assembly; you’ve got the Vietnamese for the low to the mid; you’ve got the Thais from mid to the high; you’ve got Malaysia for the higher end, and then you have Singapore for the absolute top and they’re all in relative proximity.

In the rest of the world, places where that exists with rule of law are relatively limited. But the bulk of it is on the US-Mexico border zone. Which means you need to look for the population centers north of the border, who have spare employment capacity and enough physical infrastructure in proximity to population sources south of the border. The logical choices are San Antonio, El Paso, San Diego and Tucson, Arizona, in that order.

These are the places we’re going to just see gobs of electronics manufacturing going in and complementing and in many cases surpassing the manufacturing that was there in the first place. You think that’s too aggressive? No, you’re entitled to your opinion. But think of it this way. If we don’t do it, if San Antonio, El Paso and the rest don’t do this, we don’t have stuff. So from my point of view, this is a really easy sell.

-

Are Russia’s hypersonic missiles too good to be true?

Russia has reportedly used five of its new hypersonic Zircon missiles to target Kyiv since the beginning of 2024. Russia claims that these sea-based missiles, boasting a range of 625 miles and capable of traveling at nine times the speed of sound, are part of its family of “superweapons” aimed at penetrating the U.S. missile…

-

Norway sending F-16s to Ukraine

In recent months, the need for Ukrainian air defenses has grown more urgent. As U.S. aid is unable to pass through Congress, Ukraine’s European allies have been stepping up to provide what they can. Norway is now the latest nation to pledge F-16s to Ukraine, not only to defend Ukrainian airspace, but also for the…

-

Russians targeting civilian emergency crews in Ukraine

Russian forces are applying a brutal tactic in their war on Ukraine. The tactic, “double tap,” includes an initial strike on a specific civilian target of some value, followed by a second strike intentionally designed to kill the emergency first responders, medical staff, firefighters, and other key personnel dispatched to the location of the first…

-

Iranian strike on Israel not intended to provoke regional war

Rising tensions in the Middle East boiled over again on Saturday, April 13, when Iran launched a direct attack against Israel with over 300 combined armed drones, ballistic missiles and cruise missiles. The attack follows decades of simmering conflict between the two nations, amplified most recently by Israel’s invasion of Gaza and a strike on…

-

The trouble with ‘good’ demographics

Declining birth rates throughout much of Western Europe and America, and in other developed nations like Japan, have alarmed social scientists. Concern is most acute in nations where a shrinking workforce will be expected to pay for the rising costs of a much larger retiring population. But on the opposite end of this spectrum, rapid…

Latest Stories

-

Getty Images

Getty Images

More Dems signal willingness to save Johnson from speakership vote

-

Getty Images

Getty Images

NASA worm returns as interest in space grows around the world

-

Reuters

Reuters

SF DA seeks restitution for drivers delayed by Golden Gate Bridge protest

-

Getty Images

Getty Images

Mexico disrupts China’s potential plan to infiltrate US EV market

-

Getty Images

Getty Images

Free speech fight after USC cancels valedictorian’s speech

Popular Opinions

-

In addition to the facts, we believe it’s vital to hear perspectives from all sides of the political spectrum.

Latest Opinions

In addition to the facts, we believe it’s vital to hear perspectives from all sides of the political spectrum. We hope these different voices will help you reach your own conclusions.

The opinions published in this section are solely those of the contributors and do not reflect the views of Straight Arrow News.

Latest Commentary

We know it is important to hear from a diverse range of observers on the complex topics we face and believe our commentary partners will help you reach your own conclusions.

The commentaries published in this section are solely those of the contributors and do not reflect the views of Straight Arrow News.

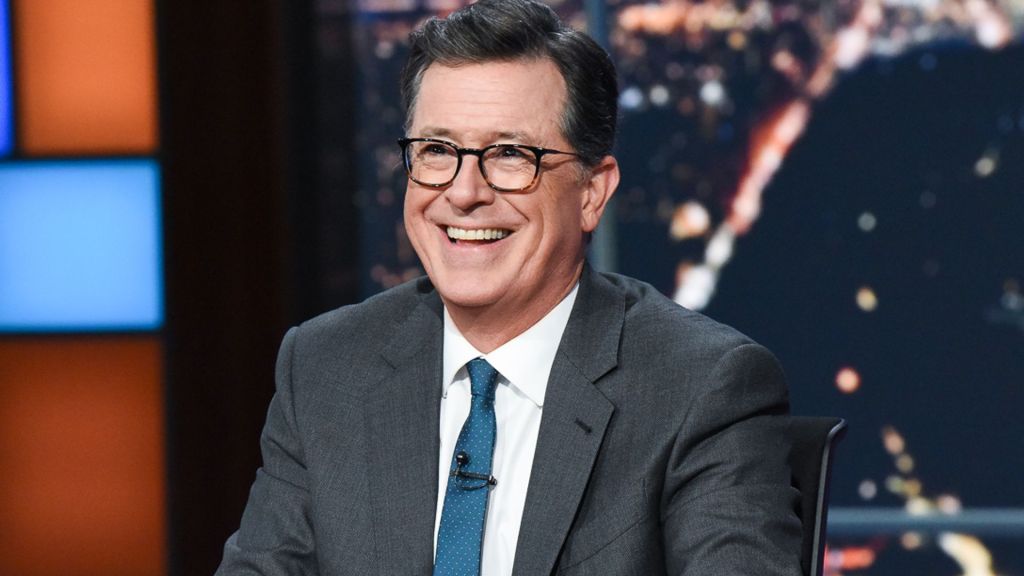

Peter Zeihan

Geopolitical StrategistNorway sending F-16s to Ukraine

Russians targeting civilian emergency crews in Ukraine

Iranian strike on Israel not intended to provoke regional war

Dr. Frank Luntz

Pollster and Political Analyst‘Take the job seriously’: Why Americans are fed up with Congress

‘If we can shrink it, it will stop growing’: Americans talk debt, deficit

‘I don’t think they care’: Undecided voters explain their reasons

Pete Ricketts

U.S. Senator for Nebraska